info@sreesakthi.edu.in

The Department of Mechanical Engineering at SSEC is known for its

commitment to engineering excellence and providing students with a comprehensive learning

experience. Collaborating with the Sree Sakthi Group of Companies, the department offers a

conducive learning environment equipped with state-of-art technical equipment and machinery,

ensuring hands-on training throughout the four years of engineering education.

Mechanical Engineering, often regarded as the "Father of Engineering," is a highly

sought-after discipline due to its vast scope and applicability across various industries.

The department caters to this breadth by offering a wide range of specialties and technical

areas, including acoustics, air-conditioning, automatic controls, computer-aided design,

energy management, fluid dynamics, robotics, biomechanics, and turbomachinery.

With its focus on excellence, the department nurtures the engineers of tomorrow by

integrating theoretical knowledge with practical hands-on projects. Emphasizing critical

thinking and the learning process, SSEC encourages students to engage in industrial visits,

providing them with real-world exposure and insights into the field.

The teaching and research programs within the department are structured to cover both

disciplinary and interdisciplinary themes. Core areas such as dynamics, controls, solid

mechanics, materials, fluid mechanics, thermodynamics, automobile engineering and design are

thoroughly explored, ensuring that students receive a comprehensive understanding of

Mechanical Engineering principles.

In summary, the Department stands as a beacon of excellence, preparing students to tackle

the challenges of the engineering world with confidence, innovation, and a deep

understanding of the fundamentals of Mechanical Engineering.

Empowering Rural Innovators: Integrating Mechanical Advancements for Student Growth

To be a globally recognized pivot of innovation and excellence in Mechanical Engineering education, research, and practice, fostering future front-runners and contributing towards sustainable technological developments

• To provide an exceptional learning environment, empowering students with cutting-edge knowledge and ethical values

• To promote interdisciplinary collaborations, engage in continuous research, and cultivate a culture of lifelong learning

• To harness innovation, meet communal needs, and serve as a vital resource for the broader community, driving impactful change

The Department of Mechanical Engineering operates with a

dedicated team of well experienced and qualified teaching faculty members and supporting

staff, all committed to academic excellence and student success. At the helm is

Dr. K.

Nandagopal, M.E., Ph.D., whose tenure spans over 17 years of experience in various

institutions including overseas experience. His vast experience enriches the department's

academic environment and strategic direction.

Under Dr. K. Nandagopal's leadership, the department boasts a

robust academic team actively pursuing their doctoral studies. The faculty collectively

brings more than a century's worth of teaching experience, with an average over ten years

per faculty member.

Specializing in various domains of mechanical engineering,

including production, design, manufacturing, industrial, thermal engineering, CAD/CAM, and

materials, the faculty members exhibit a strong commitment to professional development. They

organize and participate in a plethora of workshops, seminars, and faculty development

programs, ensuring continuous growth and skill enhancement. Additionally, faculty members

have completed numerous NPTEL courses, enhancing their expertise in various areas of

mechanical engineering.

Their dedication to research is evident through their prolific

contributions, with over three hundred research papers published in esteemed peer-reviewed

international journals and conferences over the past three academic years. This active

involvement in scholarly activities reflects the department's unwavering pursuit of

excellence and its commitment to shaping future leaders in Mechanical Engineering.

| Course Code: BE3271 Course Title: Basic Electrical and Electronics Engineering Laboratory | ||

|---|---|---|

| S. No. | Description of Equipment | Required numbers (for a batch of 30 students) |

| 1 | Verification of ohms and Kirchhoff’s Laws 1.DC Regulated Power supply (0 - 30 V variable) 2.Bread Board 3.Resistors 4.Multimeter 5.Connecting wires |

1 1 As per circuit diagram 1 As Required |

| 2 | Load test on DC Shunt Motor 1.Ammeter MC (0-20A) 2.Voltmeter MC (0-300)V 3.Rheostat 7.5 Ω, 10 A 4.Tachometer 5.Field Rheostat 175 Ω, 1.5 A 6.Connecting wires |

1 1 1 1 1 As Required |

| 3 | Load test on Self Excited DC Generator 1. DC shunt generator (0- 300V) 2. Ammeter (0-30 A), (0-2A) 3.Voltmeter (0-30V) 4.Rheostat 175Ω, 250 Ω 5.Tachometer 6.Connecting Wires |

1 1 1 1 1 As Required |

| 4 | Load Test on Induction Motor 1.Ammeter MI (0-20A) 2.Voltmeter MI (0-300)V 3.Wattmeter – 300V, 30 A 4.Tachometer – Digital 5.Connecting Wires – As Required 6.Single phase Induction motor |

1 1 1 1 As Required 1 |

| 5 | Characteristics of PN and Zener Diodes 1.PN Diode (BY127, OA79), Zener diode (6.8V, 1A) 2.Resistor 1 KΩ, 100Ω 3.Bread Board 4.DC Regulated Power supply (0 - 30 V variable) 5.Multimeter 6.Connecting wires |

1 1 1 1 1 As Required |

| 6 | Characteristics of BJT 1.Transistor (No-BC548) 2.Resistors- 1kΩ, 470KΩ, 1MΩ 3.Bread Board 4. DC Regulated Power supply (0 - 30 V variable) 5.Multimeter 6.Connecting wires |

1 1 1 1 1 As Required |

| Characteristics of SCR 1.D C Power Supply (0‐128 V) (0‐32V ) 2.Voltmeter (0‐100V) 3.SCR TYN604 4.Digital Multimeter 5. Ammeters (0‐100mA, 0-25mA, 0-1mA) 6.Resistors 1KΩ, 1KΩ 7.Bread board 8.Connecting Wires |

1 1 1 1 1 1 1 As Required |

|

| Characteristics of MOSFET 1.MOSFET (2N7000) 2.Bread board 3.Resistor (1KΩ, 100KΩ) 4.DC power supply (0‐30V) 5.Multimeter 6. Bread board 7.Connecting Wires |

1 1 1 1 1 1 As Required |

|

| 7 | Half wave and Full Wave rectifiers 1. Diodes (Si-1N4007) – 4 2.Resistor 1KΩ 3.Capacitor 100µF 4.Digital Multimeter 5.CRO 6.Transformer (6-0-6)V 7.Bread Board 8.Connecting Wires |

1 1 1 1 1 1 1 As Required |

| 8 | Study of Logic Gates 1. IC 7400, 7402, 7404, 7408, 7432, 7486 2.Digital IC trainer 3.Patch chords |

1 1 As Required |

| 9 | Implementation of Binary Adder and Subtractor 1.AND Gate IC 7408 2.X-OR Gate IC 7486 3.NOT Gate IC 7404 4.OR Gate IC 7432 5. IC Trainer Kit 6. Patch Chords |

1 1 1 1 1 As Required |

| S. No. | Description of Equipment | Required Numbers |

|---|---|---|

| 1 | Intel Octa core i9 processor | 6 GHz, 16 GB Ram, 600 s8D HD- 50 |

| 2 | Windows 11 | 50 S7D Acad License |

| 3 | Creo 9.0 | |

| 4 | Solid Works 2023 | |

| 5 | Autodesk Inventor 2023.1.1 | |

| 6 | Auto CAD 2023 |

| S. No. | Name of the Equipment | Required Numbers |

|---|---|---|

| 1 | Centre Lathes | 7 Nos. |

| 2 | Shaper | 1 No. |

| 3 | Horizontal Milling Machine | 1 No. |

| 4 | Vertical Milling Machine | 1 No. |

| 5 | Surface Grinding Machine | 1 No. |

| 6 | Cylindrical Grinding Machine | 1 No. |

| 7 | Radial Drilling Machine | 1 No. |

| 8 | Lathe Tool Dynamometer | 1 No. |

| 9 | Milling Tool Dynamometer | 1 No. |

| 10 | Gear Hobbing Machine | 1 No. |

| 11 | Gear Shaping Machine | 1 No. |

| 12 | Arc welding transformer with cables and holders | 2 Nos. |

| 13 | Oxygen and Acetylene gas cylinders, blow pipe and other welding outfit | 1 No. |

| 14 | Moulding table, Moulding equipments | 2 Nos. |

| S. No. | Name of the Equipment | Required Numbers |

|---|---|---|

| 1 | Venturi meter setup | 1 No. |

| 2 | Friction Apparatus setup | 1 No. |

| 3 | Metacentric Height apparatus setup | 1 No. |

| 4 | Impact of jet setup | 1 No. |

| 5 | Centrifugal pump set up | 1 No. |

| 6 | Reciprocation pump set up | 1 No. |

| 7 | Pelton Wheel turbine set up | 1 No. |

| 8 | Stop watch | 15 Nos. |

| 9 | IM wooden seal | 15 Nos. |

| 10 | Tachometer | 1 No. |

| S. No. | Name of the Equipment | Required Numbers |

|---|---|---|

| 1 | I.C Engine – 2 stroke and 4 stroke model | 1 set |

| 2 | Apparatus for Flash and Fire point | 1 No. |

| 3 | 4-stroke Diesel Engine with mechanical loading | 1 No. |

| 4 | 4-stroke Diesel Engine with hydraulic loading | 1 No. |

| 5 | 4-stroke Diesel Engine with electrical loading | 1 No. |

| 6 | Multi-Cylinder Petrol Engine | 1 No. |

| 7 | Single Cylinder Petrol Engine | 1 No. |

| 8 | Data Acquisition system with any one of the above engines | 1 No. |

| 9 | Steam Boiler with turbine setup | 1 No. |

| S. No. | Name of the Equipment | Required Numbers |

|---|---|---|

| 1 | Micrometer | 5 Nos. |

| 2 | Vernier Caliper | 5 Nos. |

| 3 | Vernier Height Gauge | 2 Nos. |

| 4 | Vernier Depth Gauge | 2 Nos. |

| 5 | Slip Gauge Set | 1 No. |

| 6 | Gear Tooth Vernier | 1 No. |

| 7 | Sine Bar | 1 No. |

| 8 | Floating Carriage Micrometer | 1 No. |

| 9 | Profile Projector / Tool Makers Microscope | 1 No. |

| 10 | Mechanical / Electrical / Pneumatic Comparator | 1 No. |

| 11 | Autocollimator | 1 No. |

| 12 | Coordinator Measuring Machine | 1 No. |

| 13 | Surface finish Measuring Equipment | 1 No. |

| 14 | Bore Gauge | 1 No. |

| 15 | Telescope Gauge | 1 No. |

| S. No. | Name of the Equipment | Required Numbers |

|---|---|---|

| 1 | Cam follower setup | 1 set |

| 2 | Motorised gyroscope | 1 No. |

| 3 | Governor apparatus – Watt, Porter, Proell and Hartnell governors | 1 No. |

| 4 | Whirling of shaft apparatus | 1 No. |

| 5 | Dynamic balancing machine | 1 No. |

| 6 | Two rotor vibration setup | 1 No. |

| 7 | Spring mass vibration system | 1 No. |

| 8 | Torsional Vibration of single rotor system setup | 1 No. |

| 9 | Gear Models | 1 No. |

| 10 | Kinematic Models to study various mechanisms | 1 No. |

| 11 | Turn table apparatus | 1 No. |

| 12 | Transverse vibration setup of a cantilever | 1 No. |

| S. No. | Name of the Equipment | Required Numbers |

|---|---|---|

| HARDWARE | ||

| 1 | Computer Server | 1 No. |

| 2 | Computer nodes or systems (High end CPU with atleast 1 GB main memory) networked to the server | 30 Nos. |

| 3 | A3 size plotter | 1 No. |

| 4 | Laser Printer | 1 No. |

| 5 | CNC Lathe | 1 No. |

| 6 | CNC Milling Machine | 1 No. |

| SOFTWARE | ||

| 7 | Any High end integrated modeling and manufacturing CAD / CAM software | 15 licenses |

| 8 | CAM Software for machining centre and turning centre (CNC Programming and tool path simulation for FANUC / Sinumeric and Heidenhain controller) | 15 licenses |

| 9 | Licensed operating system | Adequate |

| 10 | Support for CAPP | Adequate |

| S. No. | Name of the Equipment | Required Numbers |

|---|---|---|

| 1 | Guarded plate apparatus | 1 set. |

| 2 | Lagged pipe apparatus | 1 No. |

| 3 | Natural convection – vertical cylinder apparatus | 1 No. |

| 4 | Forced convection inside tube apparatus | 1 No. |

| 5 | Composite wall apparatus | 1 No. |

| 6 | Thermal conductivity of insulating powder apparatus | 1 No. |

| 7 | Pin-fin apparatus | 1 No. |

| 8 | Stefan-Boltzmann apparatus | 1 No. |

| 9 | Emissivity measurement apparatus | 1 No. |

| 10 | Parallel/counter flow heat exchanger apparatus | 1 No. |

| 11 | Single / two stage reciprocating air compressor | 1 No. |

| 12 | Refrigeration test rig | 1 No. |

| 13 | Air-conditioning test rig | 1 No. |

The Fluid Mechanics laboratory is designed to examine the properties of fluids and to conduct experiments involving both incompressible and compressible flow. Facilities are available for investigating the fundamentals of fluid statics as well as kinematics and kinetics of fluid flow to enhance the hands-on experience of our students. It is an introductory course where flow behavior, fluid forces and analysis tools are introduced. The goals of the experiments include determination of forces generated when fluid flow takes place over a solid object, applications of the control volume approach, flow measurements, major and minor losses in the flow and to determine the state of flow using Reylods experiment.

Strength of material laboratory provides the basic knowledge of strength of materials and the students can perform different tests on variety of materials. Experiments are performed to measure the properties of materials such as impact strength, tensile strength, compressive strength, hardness etc. The laboratory is equipped with Servo Controlled Universal Testing Machine, Servo Controlled Compression Testing Machine, Digital Hardness Testing Machine, Digital Rebound Hammer etc. The Strength of material laboratory is effectively utilized by the undergraduate students in learning the principles and procedure involved in various material testing conforming to the standards.

The purpose of thermal engineering laboratory is to give conceptual and principles involving in thermal science, especially focusing on Internal Combustion Engine, Steam Generators and Compressors. The mobility sector utilizes IC combustion engine which serves as the heart of automobile industry. The study of IC engines is vital for any mechanical engineer. Students learn about the measurement of performance, retardation, heat balance, frictional power, etc. Study and testing of various oil properties for using as a fuel and lubricant in internal combustion engine and thermal systems.

The objective of this lab is to understand the concepts of conduction, convection and radiation practically in various thermal systems to Undergraduate and Postgraduate students through a series of experiments. Students have a fairly good understanding of the theory underlying the experiments and the entire lab course is innovatively designed so that classroom lectures precede the lab work. The Heat Transfer Laboratory is equipped with test facilities for doing research within internal combustion engines for energy conversion.

Manufacturing Technology Laboratory is a well-equipped laboratory which provides ideas on the practical knowledge of several steps of casting, pattern usage, mould creation, gating design; produce a casting and check casting defects. This laboratory is scheduled for 3rd semester Mechanical Engineering students. Apart from curriculum, some additional experimental setups are there which help the students to enhance their knowledge. Students also get opportunity to implement their ideas through various application oriented micro projects.

The objective of this lab is to impart practical knowledge on design and analysis of mechanisms in the machine tools. In Dynamics of Machines Laboratory, the students are doing the experiments related to their theory subjects like Engineering Mechanics, Machines and Mechanisms & Fundamentals of Vibration and Noise. Various equipments like governors, gyroscopes, balancing machines and universal vibration testing facilities are available to understand machine dynamics.

The purpose of this laboratory is to familiarize students with laboratory measuring devices, to study the measurement methods, to learn proper measuring techniques through simple measurements of mass, length and time, and to learn to express the results of calculations so as to correctly reflect the effects of measurement uncertainty. Examples of the machines, equipments and instruments are included in the IED Metrology Lab.

The CAD/CAM laboratory provides the computer knowledge on design and the skills on designing software. The students can draft the model in both 2D and 3D objects and analysis of the parts can be carried out. The software like AUTOCAD, CREO, SOLIDWORKS, MASTERCAM, ANSYS are available for the students to practise on it.

The Mechatronics Laboratory is one of the important labs of the department that serves academics as well as research. The lab caters the need to provide multi-domain knowledge and system level integration which is expected to be the key role for a mechatronics engineer.

| S. No. | Name of the student | Event | Date | Venue | Recognition/ Participation |

|---|---|---|---|---|---|

| ACADEMIC YEAR 2016-17 | |||||

| 1 | SAM NIRMAL B | ENTRPRENEURSHIP AWARENESS CAMP | 16-07-2016 | DEERAJ LAL GANDHI COLLEGE OF TECHNOLOGY | PARTICIPATED |

| 2 | DURAIYARASAN R | WORKSHOP ON COMPUTATIONAL FLUID DYNAMICS | 12-08-2016 | SNS COLLEGE OF ENGINEERING AND TECHNOLOGY | PARTICIPATED |

| 3 | BALAKUMARAN P | ||||

| 4 | BALAJI S | ||||

| 5 | GOWTHAM B | ||||

| 6 | DHANUSH KUMAR D | ||||

| 7 | SRINIVASAN S | WORKSHOP ON AUTOMOBILE MECHANICS AND IC ENGINE | 12-08-2016 | KONGU ENGINEERING COLLEGE | PARTICIPATED |

| 8 | ARJUN RAJ N | CAD MODELLING | 01-03-2017 | SASURIE ACADEMY OF ENGINEERING | PARTICIPATED |

| 9 | BALAKUMARAN P | PAPER PRESENTATION | 01-03-2017 | SASURIE ACADEMY OF ENGINEERING | PARTICIPATED |

| 10 | MADHAN PRASATH M | CAD MODELLING | 01-03-2017 | SASURIE ACADEMY OF ENGINEERING | PARTICIPATED |

| 11 | ASHWIN KUMAR V | AUTO AND AGRI EXPO 2017 | 17-03-2017 | KONGU ENGINEERING COLLEGE | PARTICIPATED |

| 12 | SOUNDAR K | ||||

| 13 | SURESH K | ASSEMBLING AND DISMANTLING | 28-03-2017 | UNITED INSTITUTE OF TECHNOLOGY | PARTCIPATED |

| 14 | MOHAMED AZEESH Y | AUTO AND AGRI EXPO17 | 17-03-2017 | KONGU ENGINEERING COLLEGE | PARTICIPATED |

| 15 | SIVA PRAKASH D | ASK ME | 28-03-2017 | UNITED INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 16 | RAMESH D | CAD CONTEST | 28-03-2017 | UNITED INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 17 | NITHIN KUMAR R | WORKSHOP ON INTERPRETATION OF ENGINEERS DRAWING | 04-03-2017 | SNS COLLEGE OF ENGINEERING | PARTICIPATED |

| 18 | KARUPPAIAH P | WORKSHOP ON INTERPRETATION OF ENGINEERS DRAWING | 04-03-2017 | SNS COLLEGE OF ENGINEERING | PARTICIPATED |

| 19 | DINESH KUMAR K | WORKSHOP ON INTERPRETATION OF ENGINEERS DRAWING | 04-03-2017 | SNS COLLEGE OF ENGINEERING | PARTICIPATED |

| 20 | PADALINGAM SHIVA SHANKARAN | WORKSHOP ON INTERPRETATION OF ENGINEERS DRAWING | 04-03-2017 | SNS COLLEGE OF ENGINEERING | PARTICIPATED |

| S. No. | Name of the student | Event | Date | Venue | Recognition/ Participation |

|---|---|---|---|---|---|

| ACADEMIC YEAR 2017-2018 | |||||

| 1 | VENKATESHWARAN M | NATIONAL LEVEL TECHNICAL SYMPOSIUM- MR. MECHANIC | 31-01-2018 | SNS ENGINEERING COLLEGE | PARTICIPATED |

| 2 | HARI S | CAD CONTEST | 20-03-2018 | SREE SAKTHI ENGINEERING COLLEGE | PARTICIPATED |

| 3 | NAVEEN M | TECHNICAL QUIZ | 06-04-2018 | SREE SAKTHI ENGINEERING COLLEGE | PARTICIPATED |

| 4 | VIJAY S | PAPER PRESENTATION | 06-04-2018 | SREE SAKTHI ENGINEERING COLLEGE | PARTICIPATED |

| S. No. | Name of the student | Event | Date | Venue | Recognition/ Participation |

|---|---|---|---|---|---|

| ACADEMIC YEAR 2018-2019 | |||||

| 1 | SUBRAMANIAN P | PAPER PRESENTATION | 16-02-2019 | SRI RENGANATHAR INSTITUTE OF ENGINEERING AND TECHNOLOGY | PARTICIPATED |

| 2 | SUBRAMANIAN P | CAD MODELLING | 16-02-2019 | SRI RENGANATHAR INSTITUTE OF ENGINEERING AND TECHNOLOGY | PARTICIPATED |

| 3 | SUBRAMANIAN P | CAR QUIZ | 16-02-2019 | SRI RENGANATHAR INSTITUTE OF ENGINEERING AND TECHNOLOGY | PARTICIPATED |

| 4 | SUBRAMANIAN P | ASK ME | 16-02-2019 | SRI RENGANATHAR INSTITUTE OF ENGINEERING AND TECHNOLOGY | PARTICIPATED |

| 5 | SIVA SUBRAMANIAN M | PAPER PRESENTATION | 14-02-2019 | SREE SAKTHI ENGINEERING COLLEGE | PARTICIPATED |

| 6 | VENKATRAMAN K | CAD MODELLING | 18-03-2019 | SREE SAKTHI ENGINEERING COLLEGE | PARTICIPATED |

| 7 | BALAMURUGAN N | RUBICKS CUBE | 18-03-2019 | SREE SAKTHI ENGINEERING COLLEGE | PARTICIPATED |

| 8 | VISHNU N R | WATER ROCKETRY | 18-03-2019 | SREE SAKTHI ENGINEERING COLLEGE | PARTICIPATED |

| 9 | YOGESH S | PAPER PRESENTATION | 18-03-2019 | SREE SAKTHI ENGINEERING COLLEGE | PARTICIPATED |

| S. No. | Name of the student | Event | Date | Venue | Recognition/ Participation |

|---|---|---|---|---|---|

| ACADEMIC YEAR 2021-2022 | |||||

| 1 | AHAMED RINEESH A | TECHNICAL QUIZ | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | FIRST PRIZE |

| 2 | KARTHIKEYAN S | ASSEMBLING AND DISASSEMBLING | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | THIRD PRIZE |

| 3 | SRIDHARAN R | ASSEMBLING AND DISASSEMBLING | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | THIRD PRIZE |

| 4 | SACRETES P | ASSEMBLING AND DISASSEMBLING | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | THIRD PRIZE |

| 5 | VEL RAJ P | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 6 | HARIKARAN A | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 7 | BALAVIGNESH S | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 8 | VASANTHA KUMAR K | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 9 | JAISURIYA P | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 10 | BOOPESH S | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 11 | PRASANTH J | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 12 | VIKRAMAN N | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 13 | GOWTHAM R | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 14 | MANNAN A | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 15 | SACRETES P | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 16 | DHANUSH A | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 17 | SIVABALAN S | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 18 | GOWTHAM M | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 19 | SRIDHARAN R | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 20 | AHAMED RINEESH A | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 21 | AASHIQ SALMAN A | MECHTRIGERZ-2K22 | 25-03-2022 | HINDHUSTHAN INSTITUTE OF TECHNOLOGY | PARTICIPATED |

| 22 | HARIKARAN A | WORKSHOP ON DISMANTLING AND ASSEMBLING OF AUTOMOBILE ENGINES | 13-10-2021 | SREE SAKTHI ENGINEERING COLLEGE | PARTICIPATED |

| 23 | SARAVANAN M | WORKSHOP ON DISMANTLING AND ASSEMBLING OF AUTOMOBILE ENGINES | 13-10-2021 | SREE SAKTHI ENGINEERING COLLEGE | PARTICIPATED |

| S. No. | Name of the student | Event | Date | Venue | Recognition/ Participation |

|---|---|---|---|---|---|

| ACADEMIC YEAR 2022-2023 | |||||

| 1 | GANESH B | PAPER PRESENTATION | 21, 22-02-2023 | SREE SAKTHI ENGINEERING COLLEGE | PARTICIPATED |

| 2 | AKASH M | CAD MODELLING | 21, 22-02-2023 | SREE SAKTHI ENGINEERING COLLEGE | PARTICIPATED |

| 3 | VIVEK I | MR. MECHANIC | 21, 22-02-2023 | SREE SAKTHI ENGINEERING COLLEGE | PARTICIPATED |

| 4 | HARIHARAN A K | CONNECTIONS | 21, 22-02-2023 | SREE SAKTHI ENGINEERING COLLEGE | PARTICIPATED |

| 5 | GANESH B | INTERNATIONAL CONFERENCE | 11.10.2023 | PPG INSTITUTE OF TECHNOLOGY | ATTENDED |

| 6 | ARUL MURUGAN A | INTERNATIONAL CONFERENCE | 11.10.2023 | PPG INSTITUTE OF TECHNOLOGY | ATTENDED |

| 7 | NAVEEN KUMAR | INTERNATIONAL CONFERENCE | 11.10.2023 | PPG INSTITUTE OF TECHNOLOGY | ATTENDED |

| 8 | SHANTHANU | INTERNATIONAL CONFERENCE | 11.10.2023 | PPG INSTITUTE OF TECHNOLOGY | ATTENDED |

| 9 | JAISURYA | INTERNATIONAL CONFERENCE | 11.10.2023 | PPG INSTITUTE OF TECHNOLOGY | ATTENDED |

| 10 | BALAVIGNESH | INTERNATIONAL CONFERENCE | 11.10.2023 | PPG INSTITUTE OF TECHNOLOGY | ATTENDED |

| 11 | VELRAJ | INTERNATIONAL CONFERENCE | 11.10.2023 | PPG INSTITUTE OF TECHNOLOGY | ATTENDED |

| 12 | DHANUSH | INTERNATIONAL CONFERENCE | 11.10.2023 | PPG INSTITUTE OF TECHNOLOGY | ATTENDED |

Pipelines that bring fresh water and gas lines

Towers that carry electricity to industries and houses

Cars and buses that take people where they need to go etc.

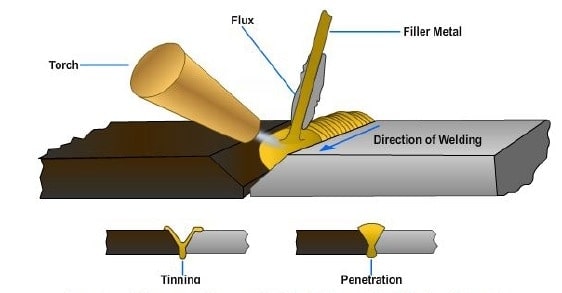

The welding is a process of joining two similar or dissimilar metals by fusion, with or without the application of pressure and with or without the use of filler metal.

Shielded metal arc welding.

Submerged arc welding.

Tungsten inert gas welding.

Plasma arc welding.

Gas metal arc welding.

Electrogas welding.

Electrosgas welding.

Types of welding joints such as Butt joint, Lap joint, Corner joint, Edge joint and Tee joint..

Positions of the welding such as Flat position, Horizontal position, Vertical position and Overhead position.

Certified Welding Inspector (AWS & CSWIP).

Certified Associate Welding Inspector.

Senior Certified Welding Inspector.

Certified Welding Educator.

Certified Radiographic Interpreter.

Certified Welding Supervisor.

Certified Welding Sales Representative.

A batch of 4th & 6th semester around 54 students of Mechanical Department along with faculty members, Mr. MIDHUN R (Asst. Professor) and Mr. SARAVANAKUMAR (Asst. Professor) visited the amusement park as well as the water treatment plant within the WONDERLA premises.

OUTCOME OF THE VISIT:

Students got a brief knowledge about the process of water purification and recycling processes

Clariflocculation process was taught in practical

Students benefited through this visit in connection with academics

Jeep trekking to SATHALANGARI VIEW POINT and HONAMANALA waterfalls.

HIGHLIGHTS:

Shooting spot

Z point

Campfire

Spots visited:

DHUBARA ELEPHANT CAMP

GOLDEN TEMPLE

NISARGADHAMA BAMBOO FOREST

ANSYS is an analyzing software used for mechanical product design and civil structure designs. It uses computer based numerical techniques to solve problems. It is FEA software by ANSYS Inc. It is widely used for analyzing solutions in the industry. The range of problems can be solved immensely. It helps engineers to design complex, highly nonlinear and large models and used to stimulate computer models of structures, electronics, or machine components for analyzing strength, elasticity, temperature etc. Most of its stimulation is performed by using ANSYS Workbench system. It also develops software for data management and backup.

It can import all kinds of CAD geometries (2D and 3D) from different CAD softwares.

It has the capability of performing advanced engineering simulations accurately.

It has the capability to optimize various features like geometrical design and boundary conditions.

It has its own customized tool called ACT which uses Python as a background scripting language.

It has the ability to integrate various physics and perform analysis.

It uses certain inputs and evaluates the product behavior to physics.

It is a general purpose software used to stimulate the interaction between physics elements like dynamic, static & fluid. It can import various geometric shapes from different CAD software and use them to perform simulations.

The uses of ANSYS are numerous in number but finally all of them lead to one single concept called profitability of organization.

Antenna design and placement: Electromagnetic simulation of antenna design and its interaction with the entire system.

Battery cell and electrode: It simulates accurate model electrochemistry before the manufacturing process.

Battery simulation: Battery modeling and simulation use multi physics to help maximize battery performance.

Autonomous software development: Develop validate and auto generate autonomous vehicle software.

It uses certain inputs and evaluates the product behavior to physics.

Flight control: Its tools are pivotal for driving the analysis & developing 3D design.

Multi physics

Electronics

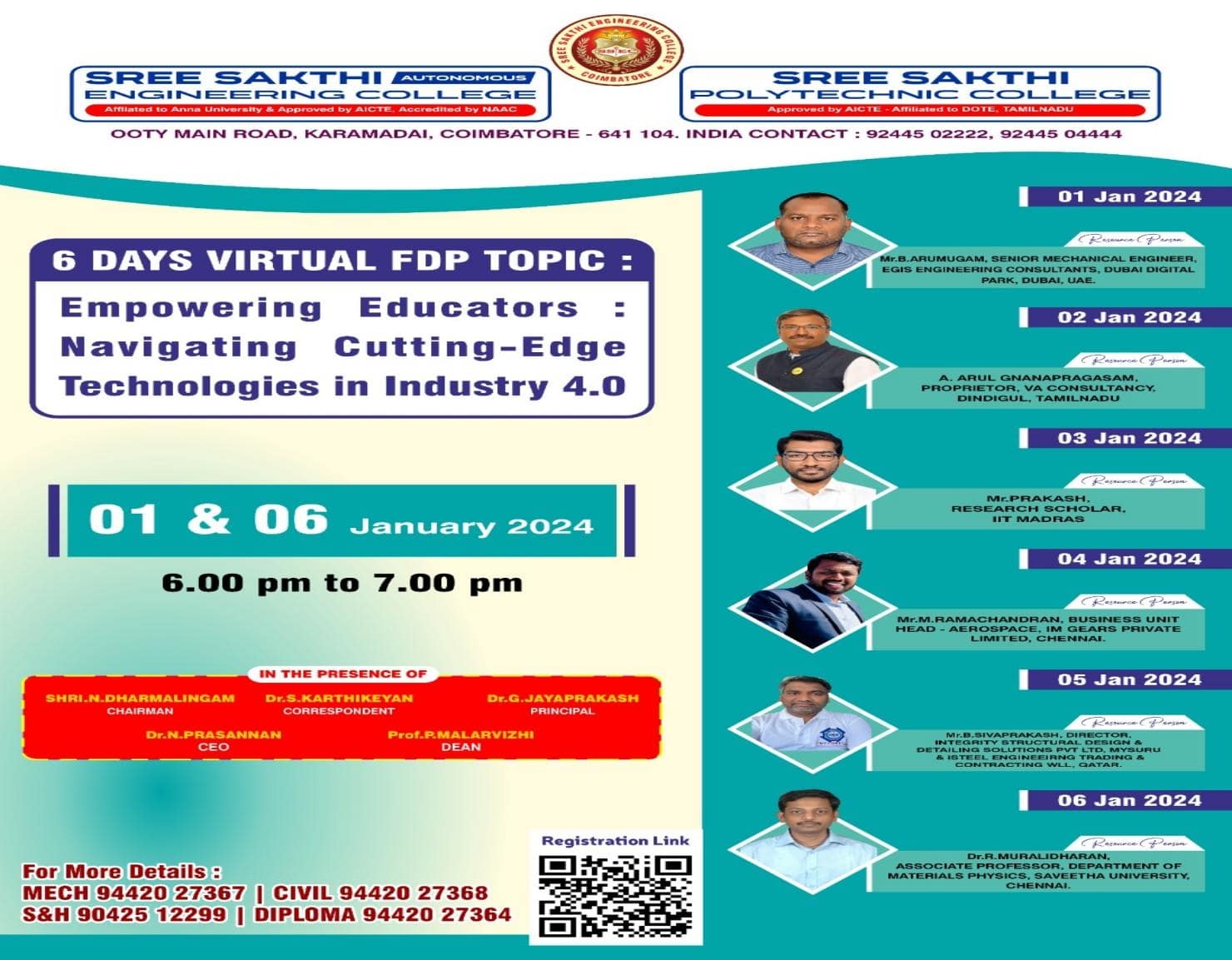

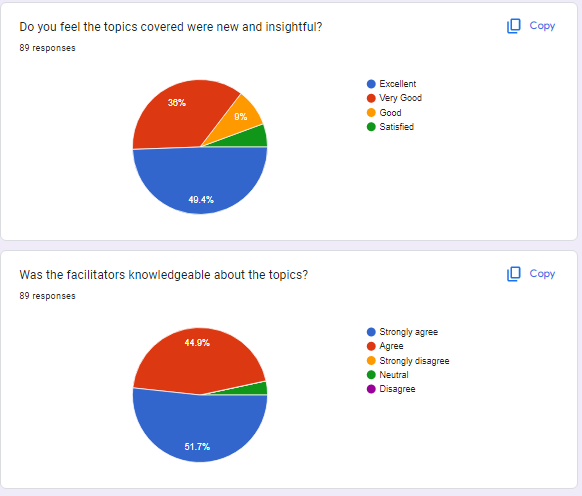

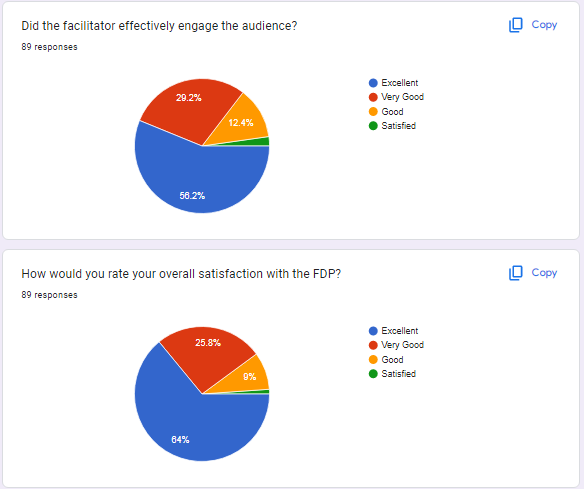

SIX DAY ONLINE VIRTUAL FACULTY DEVELOPMENT PROGRAM ON “EMPOWERING EDUCATORS: NAVIGATING CUTTING–EDGE TECHNOLOGIES IN INDUSTRY 4.O”, ORGANIZED BY THE DEPARTMENT OF MECHANICAL ENGINEERING, CIVIL, S&H & DIPLOMA from 01.01.2024 to 06.01.2024 between 6.00 p.m to 7.00 p.m.

| S. No. | Name of the student | Mobile No | Email ID | Photos |

|---|---|---|---|---|

| 1 | Mr. V. Poovarasan | 9751822873 | poovarasanflower5236@gmail.com |

|

| 2 | Mr. G. Gunavarasan | 9150375114 | gunasaro407@gmail.com |

|

| 3 | Mr. M.P. Prakash Raj | 6379805522 | prakashrajloverajl@gmail.com | - |

| 4 | Mr. V. Santhosh | 8524916117 | sandysanthosh19me019@gmail.com |

|

| 5 | Mr. S. Karthikeyan | 9487260267 | karthiksathyamoorthy32@gmail.com |

|